Thermode or stirrup soldering

In thermode or stirrup soldering, two parts previously coated with solder are heated under pressure to a temperature sufficient to cause the solder to melt and flow.

melt and flow. The current is then switched off and the thermode cools down until the solder has solidified again and a permanent electromechanical connection between the parts and the solder is formed.

connection between the parts and the solder.

Bracket soldering is very similar to piston soldering. In both processes, the heat is transferred to the component via contact. In contrast to piston soldering,

the soldering tip permanently maintains the soldering temperature, the thermode is placed relatively cold on the component and is only brought to the soldering temperature when the

soldering temperature is reached. The heat is generated in a very short time by electric current flowing through the thermode. The temperature is

controlled continuously after heating up. Since a temperature sensor is integrated into the thermode, which is evaluated by the controller of the current source,

temperature profiles can be realised precisely. The energy introduced into the heating element is controlled via pulse width modulation. The effective temperature

is measured via a sensor directly on the heating element and the power supply output is regulated according to the programmed soldering/heating profile. To accelerate cooling

the thermode is cooled with compressed air. The temperature profile can be freely programmed and the corresponding heating curve can be shown graphically on the display.

graphically on the display.

In stirrup soldering, the joining partners are usually pre-brazed. As the parts to be joined are pressed together during soldering, a small gap remains so that the amount of solder required is low.

amount of solder required is small. Only flux has to be added in advance. External solder supply of solder paste or solder wire is rather rare.

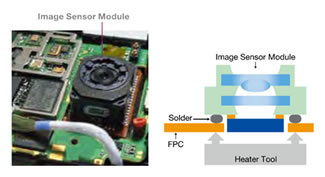

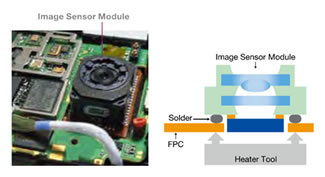

Functional principle of stirrup soldering

Functional principle of stirrup soldering

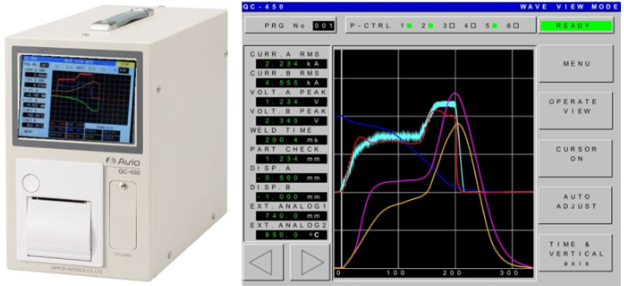

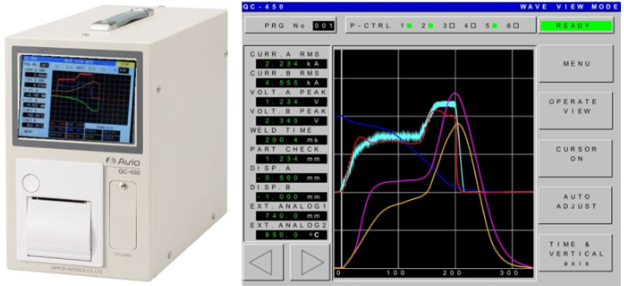

Temperature profile for stirrup soldering

Temperature profile for stirrup soldering

Example: connections

Example: connections

of a camera module

A typical temperature profile has several sections. After the solder joint is set up, it is heated up to approx. 80°C to activate the flux. Then the temperature is

the temperature is increased until the soldering temperature is reached (approx. 10-15% above the melting temperature of the solder). The melting of the solder can be detected by the setting path of the

detected by the setting path of the thermode. The soldering temperature is maintained for a few seconds until the solder wets both joining partners sufficiently. The thermode is then

and thus also the solder joint is cooled down until the solder solidifies and creates a resilient, electrically conductive connection. The thermode is then lifted off the

lifted off the solder joint. Therefore, the thermode can also be used to press the solder contacts onto the substrate. This is especially necessary for high-pole

connections and flex conductors.

Another advantage of stirrup soldering is the recording of the process parameters. Due to the relative contact area of the thermode to the solder joint, the temperature of the

of the solder joint follows the thermode temperature very quickly. The thermode has an integrated thermocouple for recording the actual temperature. Set and actual temperature

are recorded and shown on the display of the control and power unit. The pressure can be adjusted very precisely on the system head. In addition, the pressure force and

the process, the pressure force and the sink-in distance can be recorded. All data can be read out automatically via the serial interface.

Data logger, monitor and evaluation unit Q450 and screenshot

Application examples

The process is used, for example, for flexible foils with solder depots as well as for flat ribbon or stranded wire soldering and for components with many connections with a small contact distance.

small contact spacing.

Reflow soldering

FFC on board

Reflow soldering

Solder wire on board

Reflow soldering

of coaxial cables

Reflow soldering

of camera modules