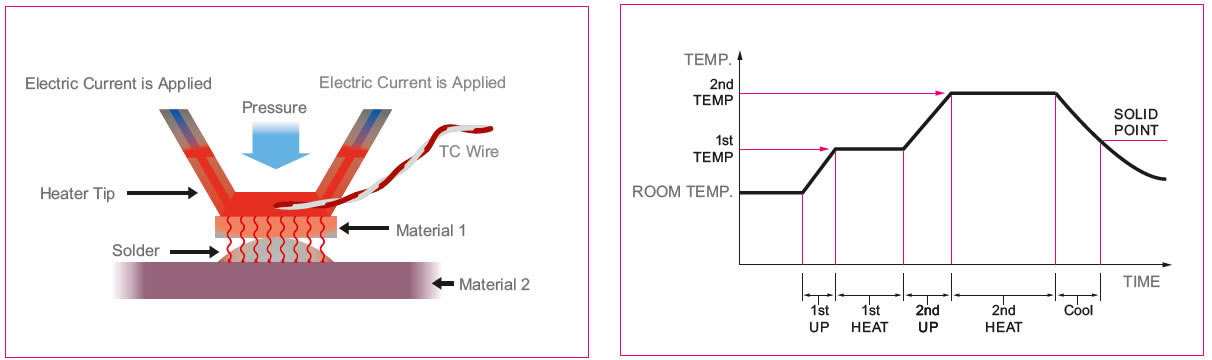

| Stirrup soldering | Temperature profile for stirrup soldering | |||||

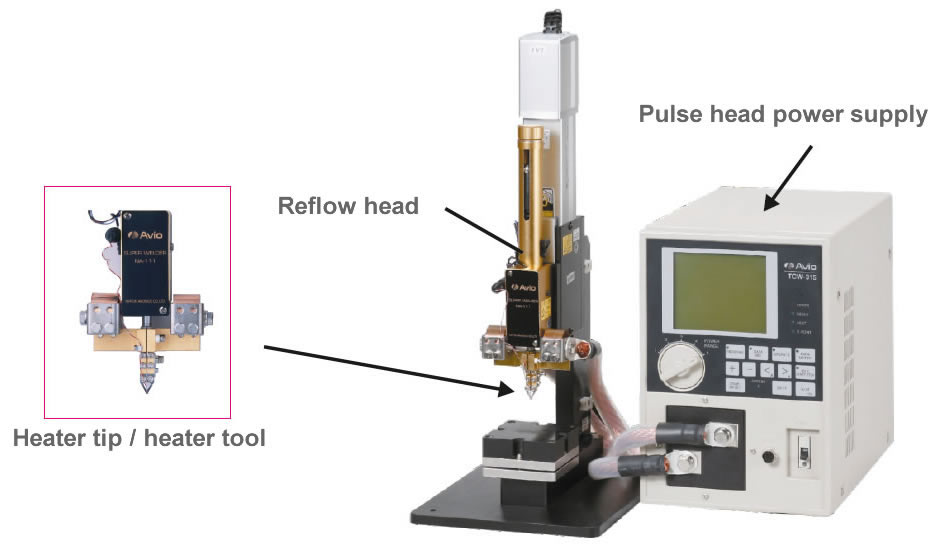

| TCW-315 | |

| Heating temperature | 20-600 °C E, J Typ 20-900 °C K Typ (optional) |

| Heating time | 000-999(×100 ms, ×10 ms) |

| Nominal power | 750 VA - 3 KVA |

| Transformer | integriert |

| Voltage values | 0.88 V, 1.24 V, 1.75 V, 2.47 V, 3.5 V |

| Power source | 1Φ AC 200 V ~ 230 V ± 10 % |

| Dimensions/Weight | 200 × 320 × 283 mm (B x T x H) ≒19,5 kg |

Since heating and cooling take place while pressure is applied, the working position is not shifted during joining.

Since heating is local and instantaneous, thermal effects on surrounding areas are limited.

Digital PID control allows good reproducibility of temperature and time.

Lead-free solder is processed by setting to high temperature and long heating time.

RS-232 & I/O facilitate integration into automated systems.

Temperature monitoring: upper and lower limit (average, maximum), profile detection error: overheating, thermocouple failure, etc.

15 stored settings: Control signal for Z-stroke and cooling air, input for auxiliary thermocouple, counter function.

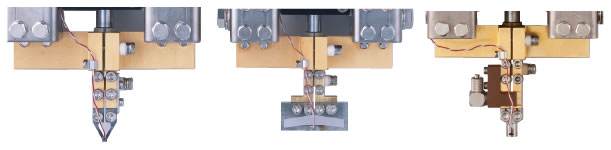

| NA-111 | NA-112 | NA-151 | NA-152 | NA-153 | |

|---|---|---|---|---|---|

| Pressure range | 0.7 - 5 N | 5 - 65 N | 1.2 - 7 N | 5 - 70 N | 20 - 150 N |

| Pressure method | Spring | ||||

| Z-Hub | depending on the z-axis | ||||

| Drive method | Motor (201PB-B), Pneumatic (NA-221) Manual (NA-231) | ||||

| Dimentions | W106 × D48 × H287 mm | W106 × D48 × H285 mm | W124 × D54.8 × H298 mm | ||

| Weight | 0,6 kg | 1,0 kg | |||

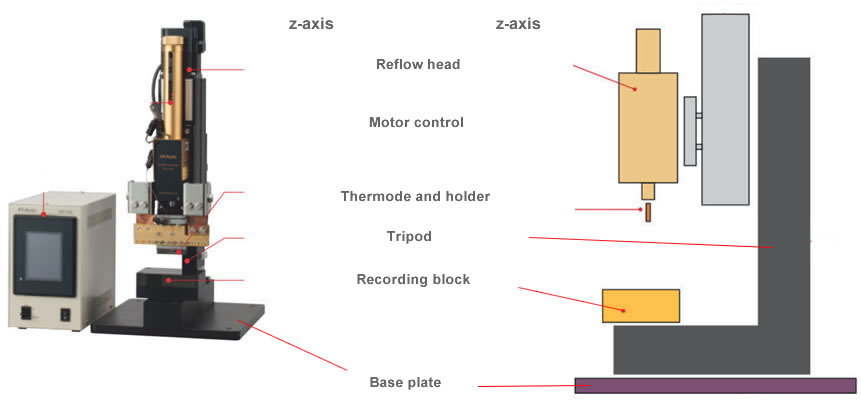

| CNT-320B | CNT-320B Touch Panel Display | 201PB-B | 202PB-B |

| CNT-320B & NA-201PB-B/NA-202PB-B | CNT-320B & NA-201PB-B | |

|---|---|---|

| Drive method | Motor | |

| Hub / Resolution | max. 50 mm / 1 µm | max. 50 mm / 10 µm |

| Power source | DC 24 V ± 10 % 4 A (Option: AC Adapter AC 100 ~ 240 V) |

DC 24 V ± 10 % 2 A (Option: AC Adapter AC 100 ~ 240 V) |

| Dimensions / Weight | CNT-320B : W120 x D315.9 x H207 mm // 3.7 kg NA-201PB-B: W57.5 x D82.5 x H311.2 mm // 2.0 kg NA-202PB-B: W74 x D103.5 x H368.6 mm // 4.5 kg |

CNT-320B : W120 x D315.9 x H207 mm // 3.7 kg NA-201PB-B: W57.5 x D82.5 x H311.2 mm // 2.0 kg |

|

Throttle for setting the speed Pneumatic cylinder Linear axis |

Foot pedal

|

||

| Pneumatic z-axis NA-221, NA-222 |

|

|||

| NA-221 | NA-222 | NA-231 | |

|---|---|---|---|

| Drive method | Pneumatic | Pneumatic | Foot pedal with bowden cable |

| Hub | max. 50 mm | max. 50 mm | max. 10 mm |

| Speed | Adjustable via throttle (Φ 4 mm hose) |

Adjustable via throttle (Φ 6 mm hose) |

|

| Compressed air | 0.4 - 0.6 MPa | 0.4 - 0.6 MPa | |

| Dimensions/Weight | W78 × D83 × H280 mm // 1,3kg | W86 × D85 × H289 mm // 2,2kg | Drive unit: W51 × D79 × H192mm // 1,0kg Foot pedal: W124 × D268 × H125mm // 2,2kg |

| Brochure Thermode Systems | |

| Do you have further questions? Please use our contact form. | |

|

Cookie Settings ATN |

|

|

Technical cookies for advanced functions of the ATN website. Please note our Privacy policy. |

|

|

Third-party provider |

|

| Cookies from Google (incl. Youtube und Google Maps)* *Google, YouTube and Google Maps are services of Google Ireland Limited. |

|

| The data protection provisions and terms of use of the respective third-party providers can be found on their website. | |