Resistance welding

What is resistance welding?

How can two metals be joined together?

The word "resistance" in "resistance welding" means to resist a certain forward movement.

resistance. It is associated with heating, as in the case of frictional heat when applying a brake.

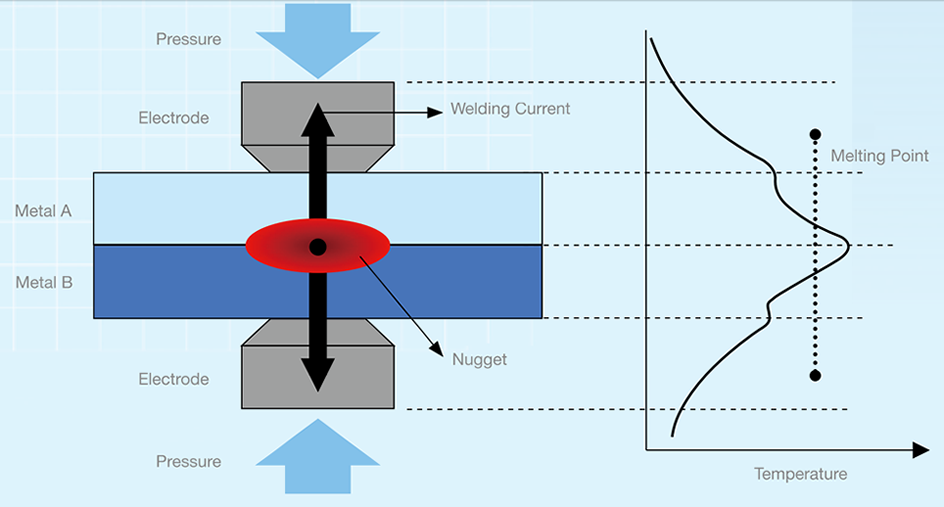

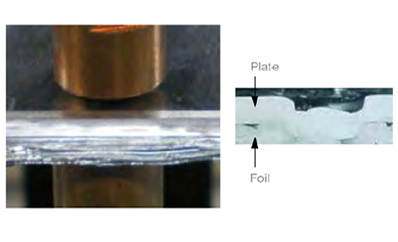

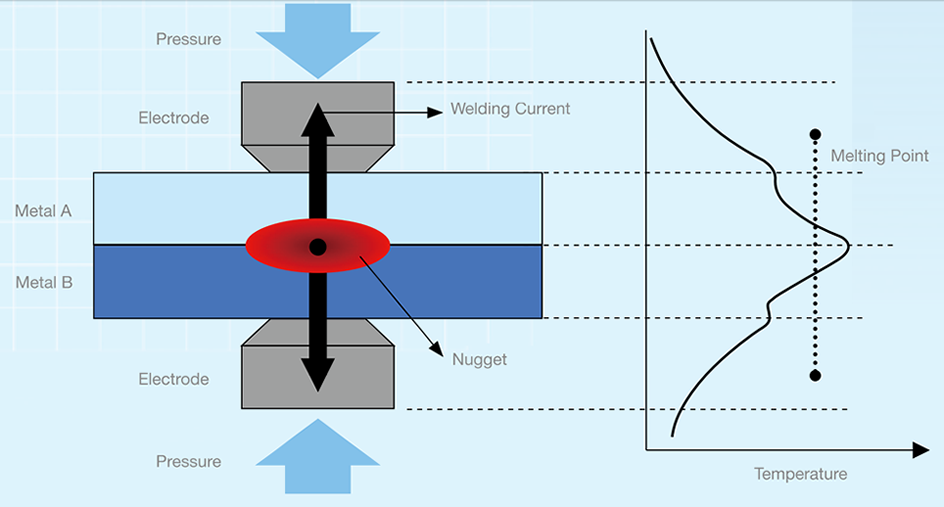

As can be seen in the model of the resistance welder (see following figure), an electric current is applied,

while pressure is applied. When the electric current tries to travel in a metal, the resistance of the metal itself and the

the resistance of the metal itself and the resistance at the joint. In particular at the

heat is generated at the junction between two metals in particular due to the higher resistance, so that

the two metals are melted and joined together. This method of joining two metals

with the help of resistance heat is called resistance welding.

Model of resistance welding

Temperature distribution during resistance welding

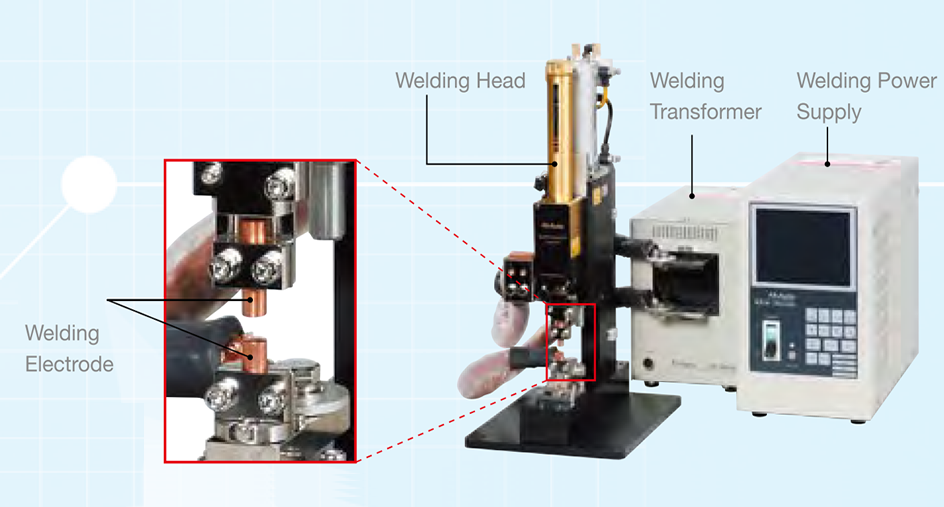

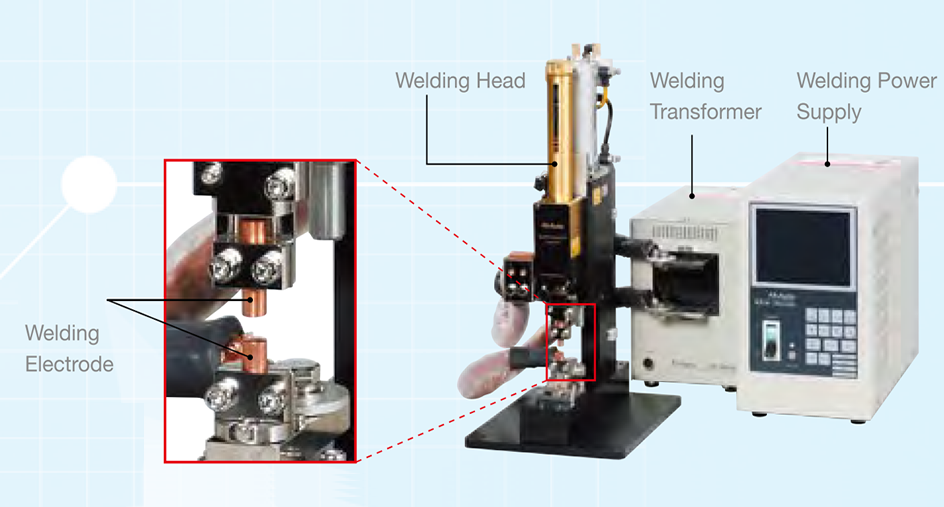

Basic configuration of a resistance welder

In resistance welding, the objects to be welded are placed between the welding electrodes and heated and pressed together with an electric current.

- The welding power supply controls the strength, time and waveform of the electric current.

- The welding transformer converts the absorbed current into a larger current with a lower voltage.

- The welding head controls the pressure that is applied.

- The welding electrode touches the object to be welded, exerts pressure and transmits the electric current.

In addition to the devices mentioned above, there are various monitors that measure the electric current or the pressure exerted.

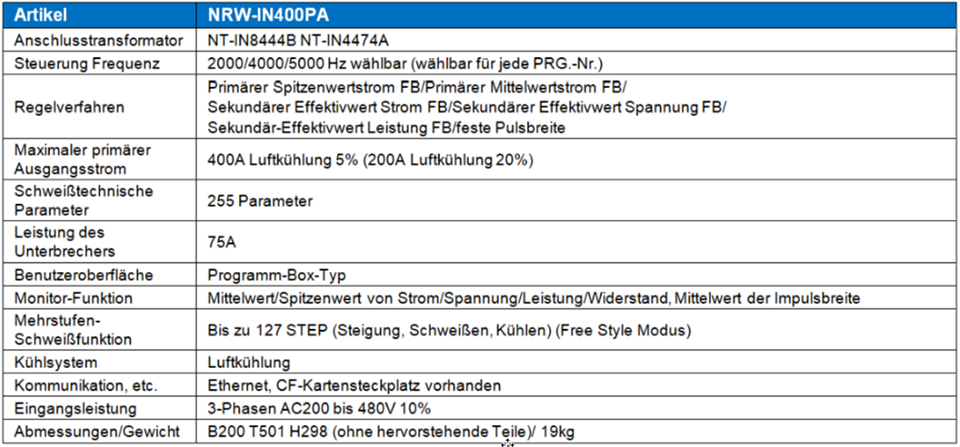

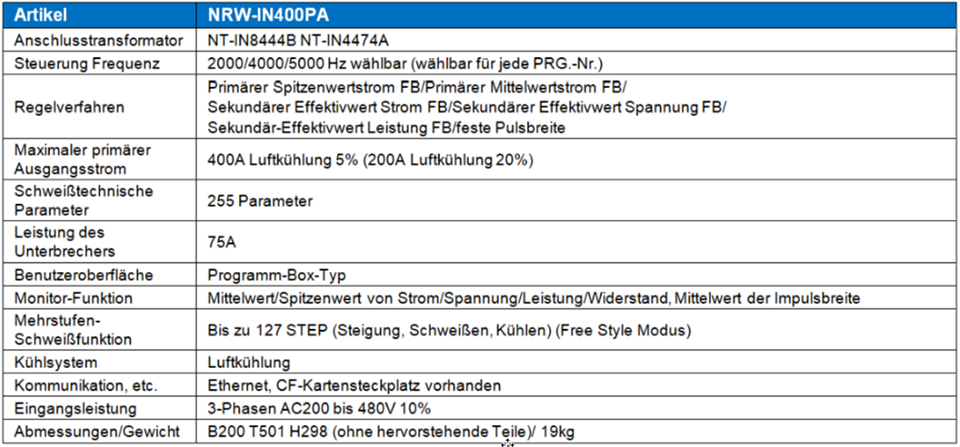

Inverter welding power supply and control

This model is a high-efficiency welding power supply that uses an inverter. It responds to the changes during

welding in real time by providing fast feedback. The highly stabilised welding current generated by the power source is optimal for the

resistance welding of precision electronic parts.

- NRW-lN400PA/NT-lN8444B

- NRW-lN400PA/NT-lN8444B

- NRW-lN16K4/NT-lN16K4

Multi-Transformer System

- Multi-control mode (constant current, voltage, power)

- Welding neck control function

- Long-term welding (maximum 3 seconds)

- Graphical display of the welding waveform on large LCD display

- Multiple monitoring function

- Welding waveform memory function

Up to 4 changeover switches with transformer can be connected to one controller and thus up to 4 welding processes can be controlled simultaneously.

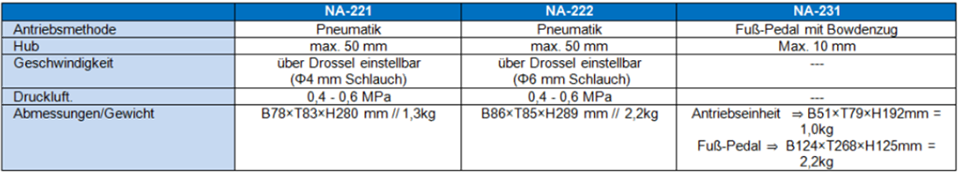

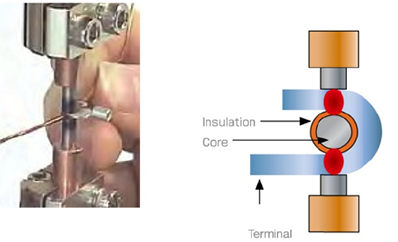

Welding head and electrode

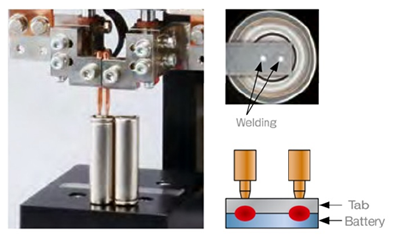

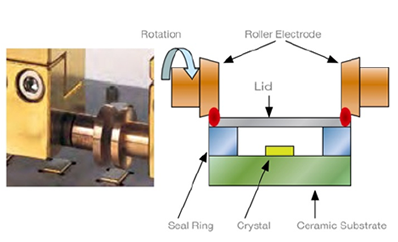

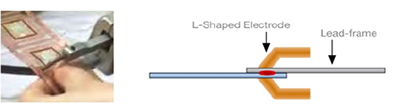

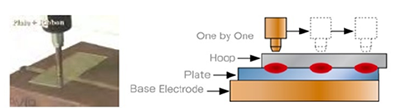

The way in which the electrode contacts the object to be welded (how the current is introduced) depends on the shape or structure of the object.

shape or structure of the object. In addition, the shape and material of the electrode and the pressure applied are also important factors in

resistance welding.

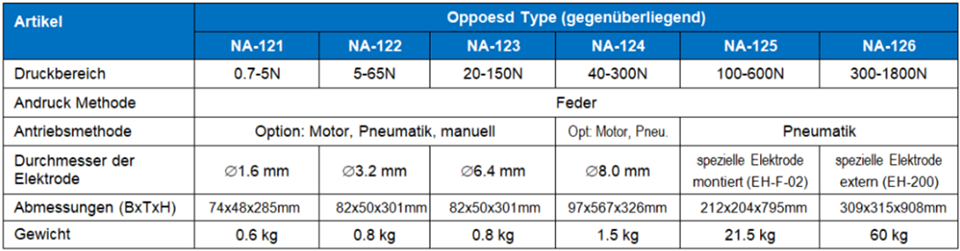

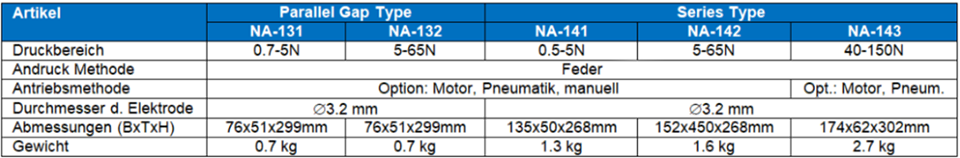

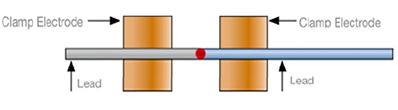

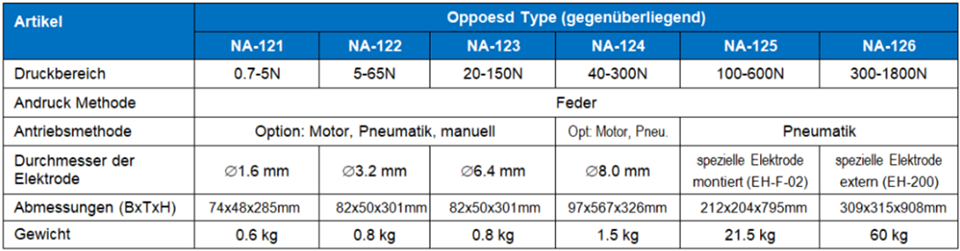

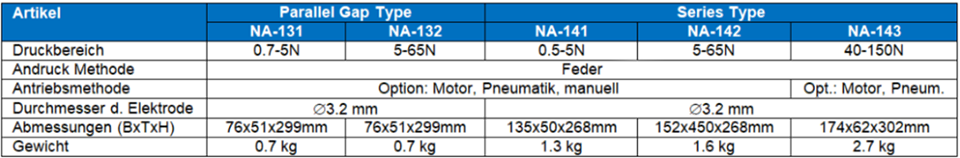

Opposed Type (opposite)

Parallel Gap Type Series Typ

Real-time monitoring of displacement and force

Power-Monitor QC-100

- Selectable display: Digital or graphic

- Simple automation through combination with system head

- Easy QC by extending the communication function (output of measured values and monitoring results)

- Easy installation of the force sensor

- High-precision measurement of the displacement of the welding material

Path monitoring QC-200

- Wave analysis by Grafikdisplay(high speed scanning with 2000 1/s)

- Measurement and assessment of 2 conditions for the welding process (measurement and assessment before/after welding)

- Trigger by applied force or displacement can be adjusted

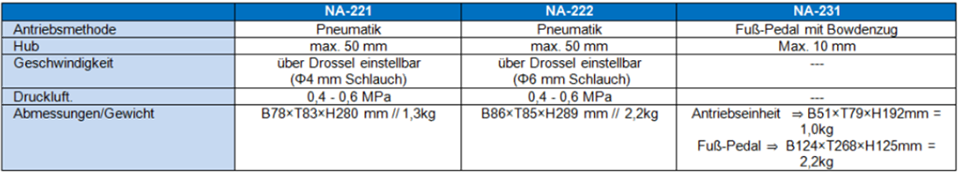

Motorised, pneumatic and mechanical Z-Hub

Motorised (electric) Z-Axis and control system

- Motor drive with 1 μm Auflolution supports precise processes

- Pressure stability function for constant contact pressure

- Position control

- High-pressure/low-temperature welding with max. 300 N force (if NA-202P is used)

- Intuitive operation via colour touch panel and step switch

- Soft landing procedure with a slow movement speed of 0.1 mm/sec

- 7 parameter sets can be stored

Pneumatische Achse Manuelle Achse

Applications

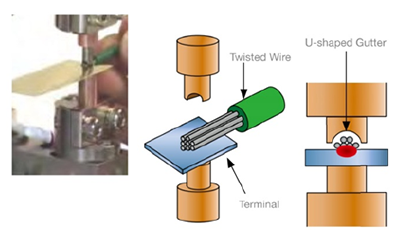

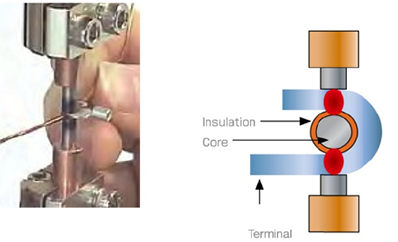

Enamelled wire and U-shaped terminal lugs

Battery pack (rechargeable battery)

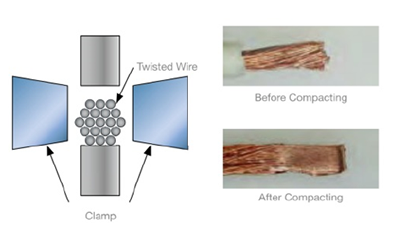

Twisted wire (compaction)

Twisted wire (compaction)

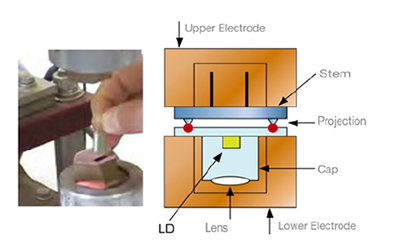

Connection of an electronic component

and connection plate

Laminated film and sheet (AI,CU)

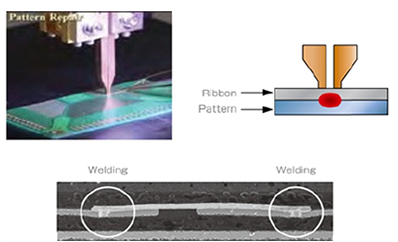

Repair wire on printed circuit board

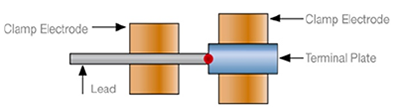

Connection and connection plate

Connecting wire and connecting wire

Lead frame and Lead frame

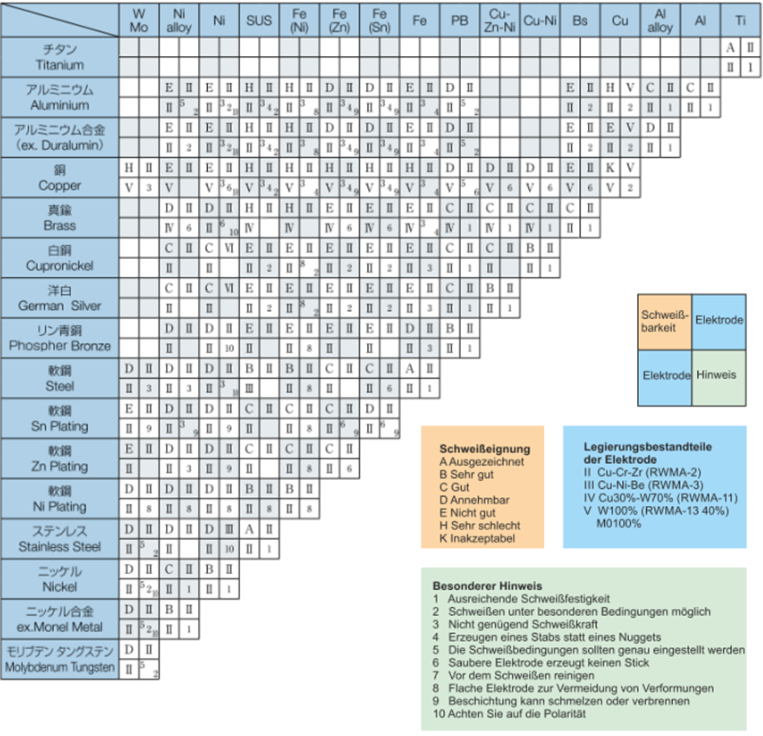

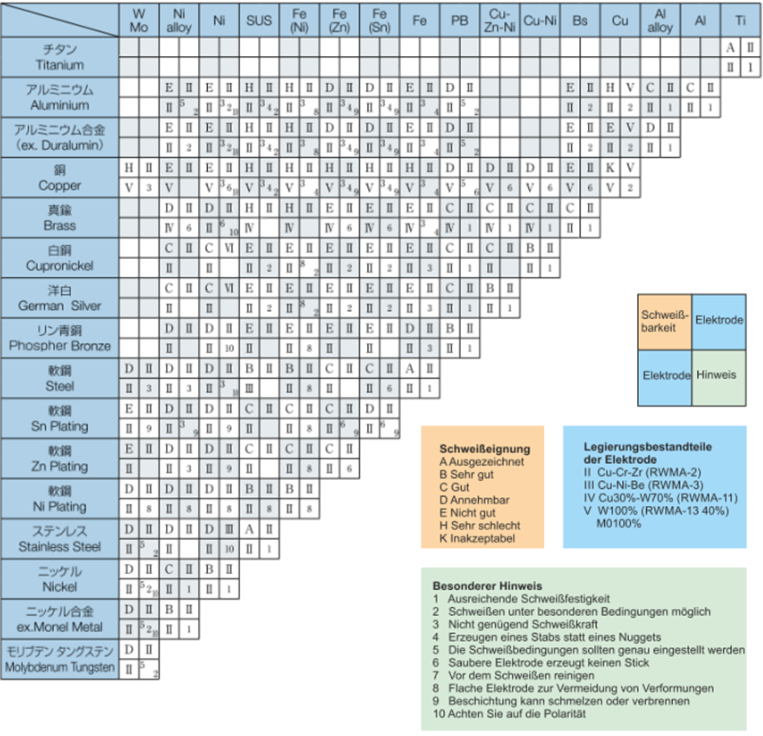

Weldability for different materials

This table is intended as a guide only and should not be interpreted as a guarantee of the welding result.

Please contact us, we will be happy to do a trial test for you.

RWMA for the electrode material designates the specifications of the Resistance Welding Manufacturing Alliance.